Discover the world of box shapes! From corrugated paper boxes to cardboard and rigid boxes, each type offers unique characteristics and design possibilities. But how do you accurately describe the dimensions and ensure a perfect fit?

Discover the secrets to effectively measure and communicate your packaging requirements to manufacturers. Learn the techniques for determining box dimensions and avoid any confusion. Plus, get access to detailed unfolding Dielines for quick reference.

I. Get to know corrugated color boxes.

These boxes consist of surface paper and corrugated paper, providing durability and strength. Find out the ideal weight and size for your boxes, as well as the different flute options to choose from. Plus, get tips on reinforcing larger boxes and designing inner trays for passing drop tests. And if you’re specifically interested in this kind of box, we’ve got you covered!

Because there are so many different box shapes of corrugated boxes, we can’t cover them all in one article. Here we only list the most commonly used PIZZA box shapes.

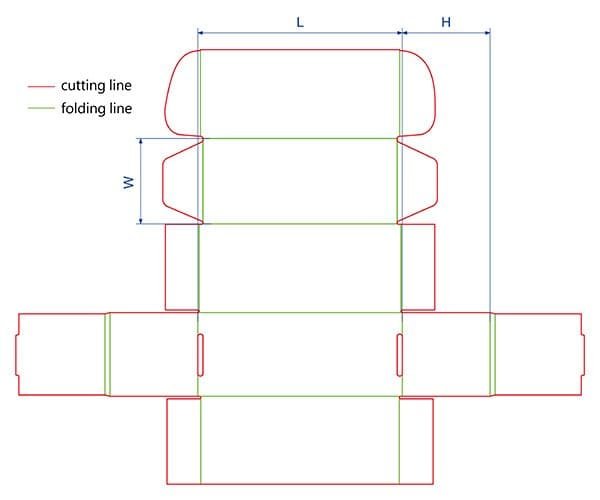

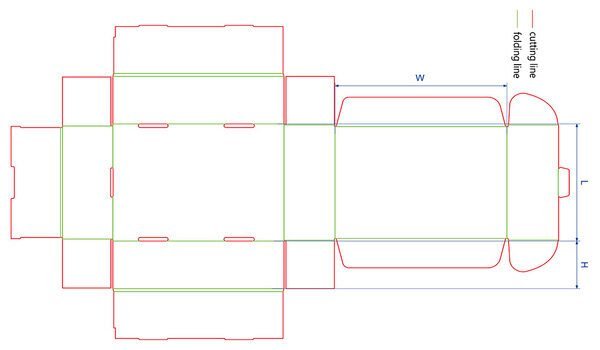

Box shape: PIZZA box shape (REFT box)

Material: Outer paper laminating corrugated paper (3 layers of amount)

Coating treatment: oiled or laminated (divided into glossy or matte), some parts can do Spot UV, hot stamping foil, and other special varnish treatments.

Length, width, and height dimensions: as shown below, L=length, W=width, H=height.

Attach the unfolding Die-line drawing and size labeling diagram as follows: (due to the different surface paper and corrugated paper, the forming thickness will be slightly different, need accurate templates for sampling or mass production, contact us).

II. Explore the world of cardboard boxes.

These boxes are perfect for lightweight, small-sized items that require a visually appealing presentation. Learn about the benefits of adding a separate inner tray for added strength. Find out everything you need to know about the most commonly used box shapes with automatic bottom closure.

Because there are too many corresponding box shapes, we can’t talk about them all in one article. Here we only list the three most commonly used boxes with automatic bottom closure to illustrate.

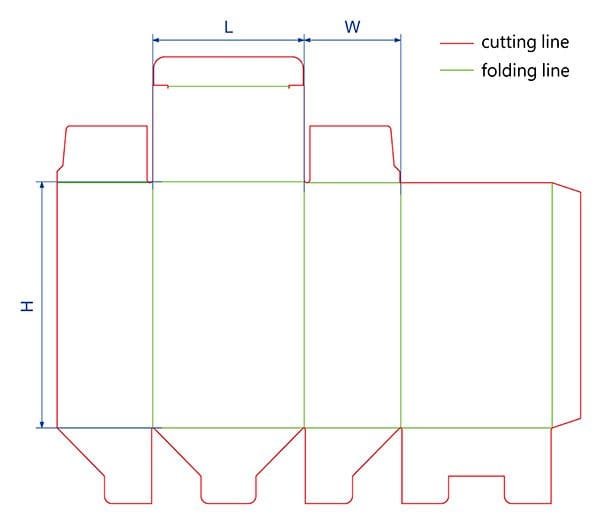

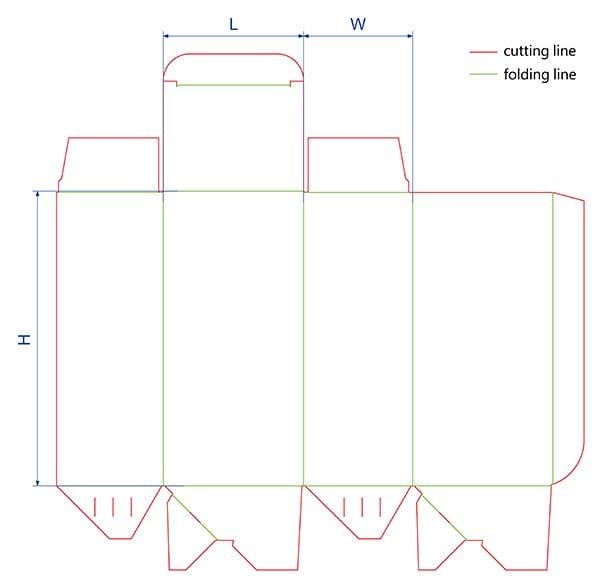

Box shape: Straight Tuck End(STE), 2 different auto bottom boxes.

Material: single-layer paper

Coating treatment: oiled or laminated (divided into glossy or matte), some parts can do Spot UV, hot stamping foil, and other special varnish treatments.

Length, width, and height dimensions: as shown in the picture below, L=length, W=width, H=height.

Attach the unfolding Die-line drawing and size labeling diagram as follows: (need accurate it, contact us directly).

III. Uncover the elegance of rigid boxes.

If you’re looking for packaging with a touch of sophistication, rigid boxes are the way to go. Made with high-quality materials, they are perfect for high-value products and high-quality packaging needs. Learn about the most commonly used box shapes. And don’t forget to check out the unfolding Dieline and size labeling diagrams for accurate measurements.

So here we also for the 2 most commonly used box shapes to explain.

Material: 128gsm-157gsm outer paper in common bonded to 600-1800gsm cardboard (can be slotted).

Coating treatment: oiled or laminated (divided into glossy or matte), some parts can do Spot UV, hot stamping foil, and other special varnish treatments.

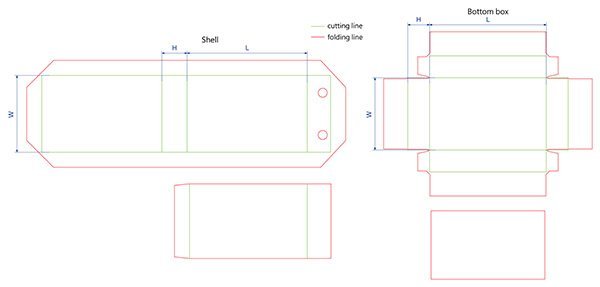

Length, width, and height dimensions: as shown in the picture below, L=length, W=width, H=height.

Attach the unfolding Dielines and size labeling diagram as follows: (different thicknesses of the chipboard for the Die-lines have to be adjusted, need an accurate it, contact us).

Ready to take your packaging to the next level? Contact us for accurate templates and expert advice now.