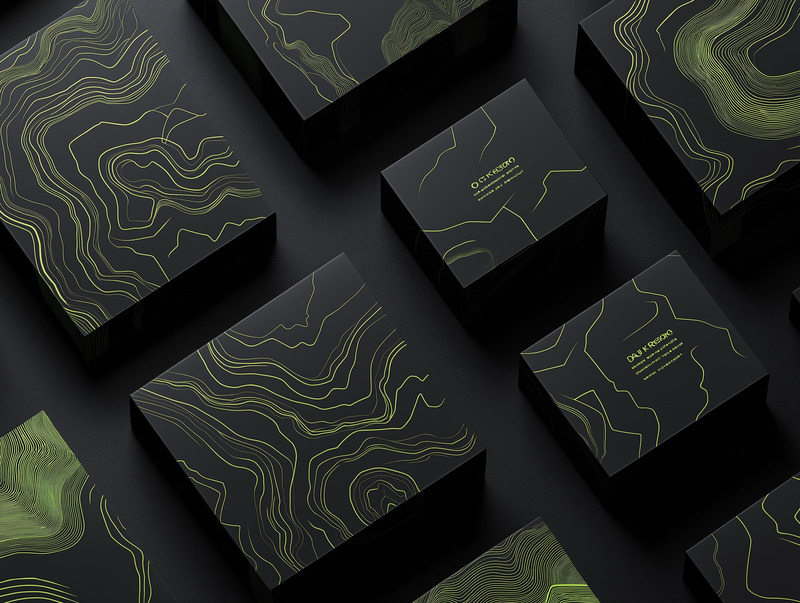

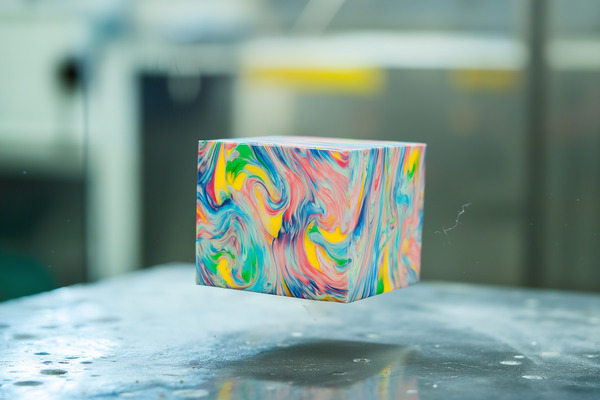

Elevate Your Brand with Custom Rigid Boxes

Discover our premium custom rigid boxes, designed to enhance your brand’s image and product protection with sophisticated, high-quality packaging solutions. Whether you’re in electronics, cosmetics, jewelry, wine and spirits, gifts, or other high-value industries, our rigid boxes ensure both security and elegance.