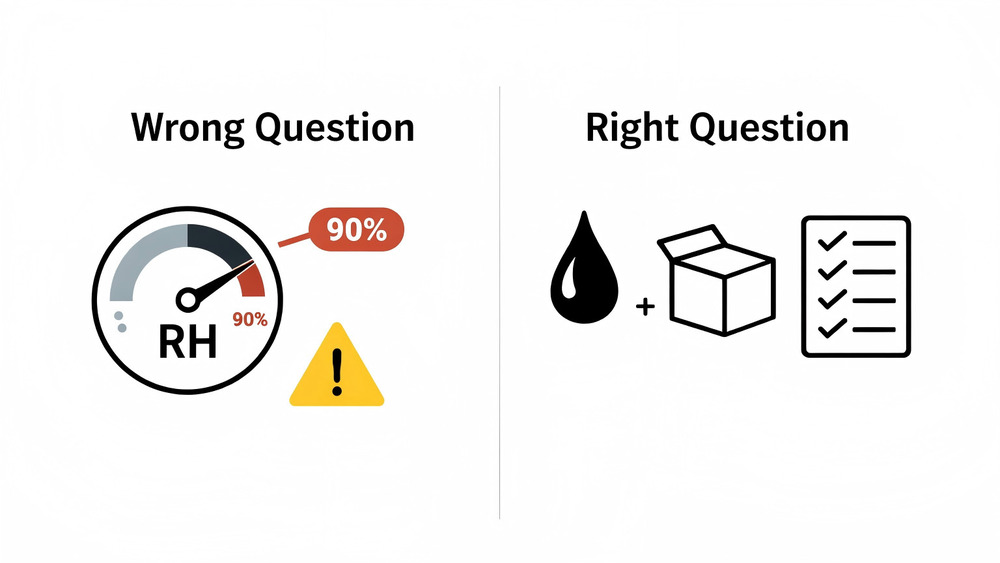

Not all humidity testing reduces risk.

This article helps you decide when high-humidity testing actually changes the decision—and when it doesn’t.

Most printed packaging fails for simple reasons: glue, folds, and process drift.

Extreme humidity tests will not fix those problems.

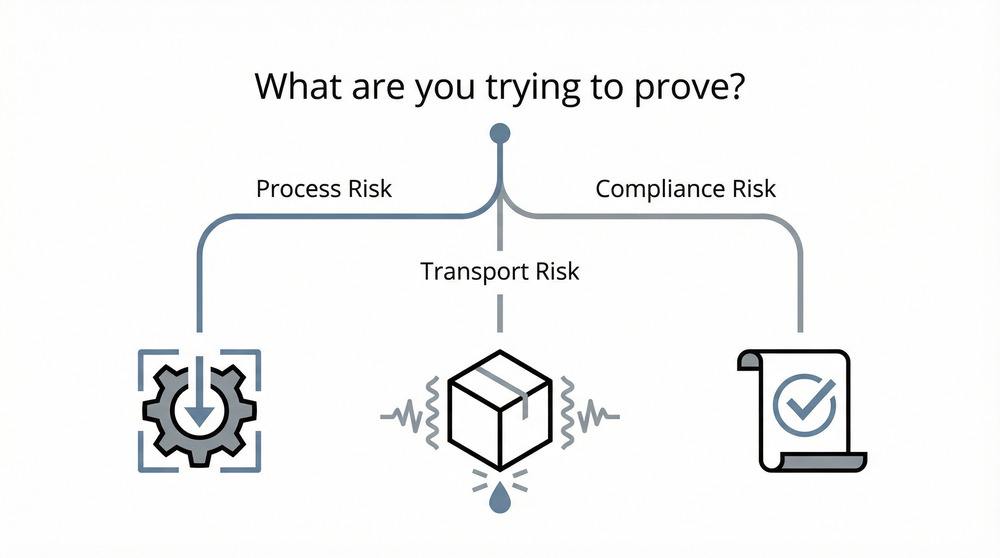

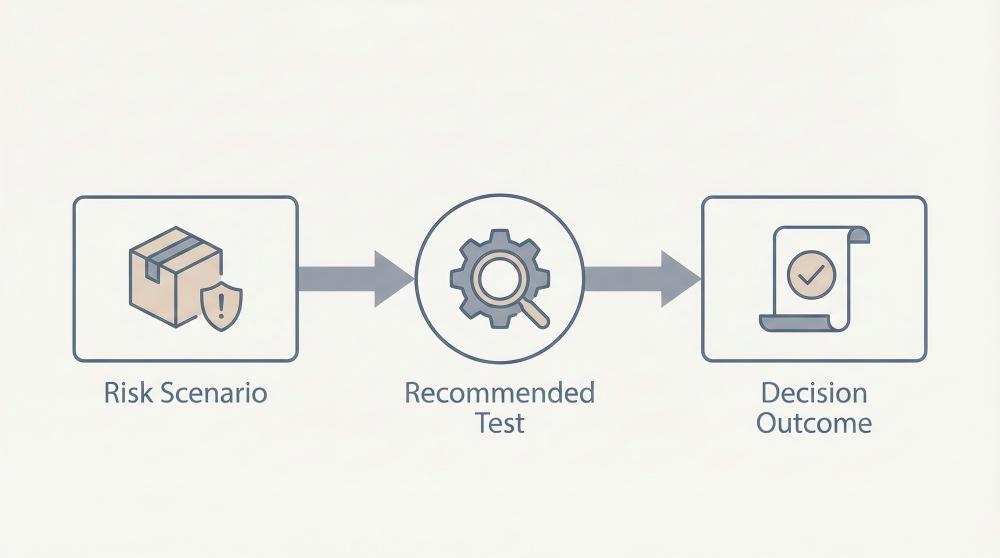

Before you test, decide what risk you are trying to prove—or rule out.

Start With the Right Question: What Are You Trying to Prove?

Many packaging projects treat test severity as a shortcut to safety.

The problem is, harsher conditions do not always lead to better answers.

Before selecting any test, you need to decide which risk you are prioritizing to reduce in advance. Testing is not proof of quality; it’s a decision tool for managing specific risks.

In practice, packaging tests aim at one of three things.

You may be checking process reliability, verifying whether production variables cause repeat failures in adhesive or folding.

You may be validating extreme transportation risk, testing rare scenarios like humidity combined with temperature swings.

Or you may be testing to satisfy compliance, meeting requirements without diagnosing underlying technical problems.

Mixing these goals causes problems.

Extreme conditions won’t fix an undefined problem, and can even hide the real risks that need attention.

Testing fails when it answers the wrong question.

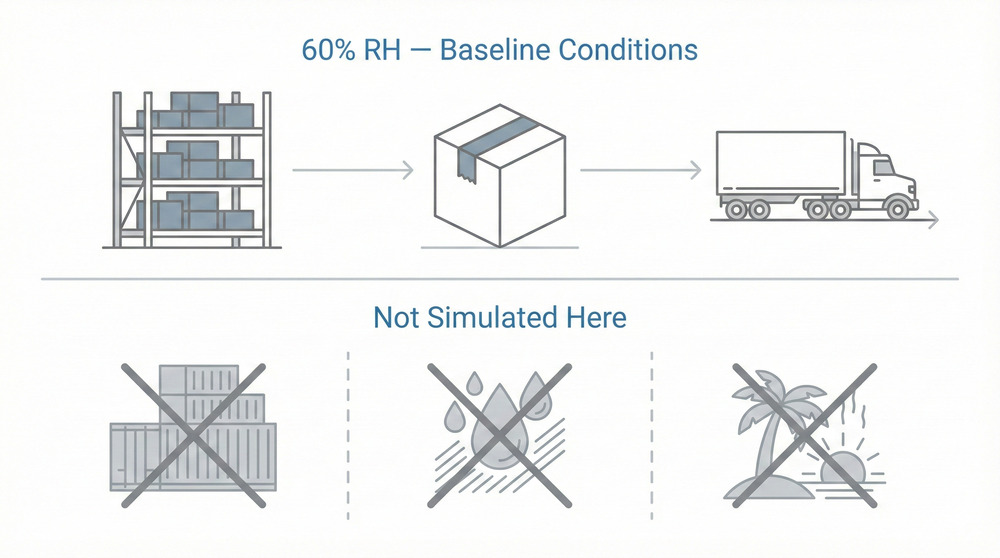

What 60% RH Testing Is Actually Used For

(Normal Storage & Shipment Baseline)

60% RH Is a Baseline, Not a Stress Test

Technically, paper fibers soak up moisture very quickly to reach an Equilibrium Moisture Content (EMC). At 60% humidity, you can already see if the glue will hold. Testing at higher levels often just tests the paper fiber’s limit, not our manufacturing quality.

60% relative humidity (RH) is used to represent normal storage and routine shipment conditions.

It reflects what printed packaging is expected to experience in warehouses and standard distribution environments.

Source: Klong Packaging Shipping Observations & Field Feedback (30-Year Internal Logs).

What it does not represent is prolonged or extreme exposure.

It does not simulate ocean freight humidity, container condensation, or sustained moisture buildup along tropical routes.

For this reason, 60% RH testing should be treated as a baseline filter, not a stress challenge.

Its purpose is to confirm stability under expected conditions—not to predict performance under rare transport events.

At 60% RH, You Are Screening for Only Three Things

At this condition, the scope of testing is intentionally limited.

You are not validating every possible risk. You are screening for only three specific failure areas.

1. Adhesive Bond Integrity

This includes double-sided tapes, laminating adhesives, and carton glues.

At around 60% RH, failures usually appear as weak initial bonding or adhesion loss after mild temperature changes—signals of material choice or application control issues.

2. Functional Failures

Here, the question is whether the package can still function as designed.

Lids that do not stay closed, tuck flaps that spring back, misaligned magnets, or fold lines that rebound all indicate functional instability.

3. Process Stability

This is about repeatability.

Can the same result be achieved across batches, and do small shifts in process parameters trigger visible instability? Marginal processes tend to surface here.

If packaging cannot remain stable at around 60% RH, it is a process issue — not a transportation issue.

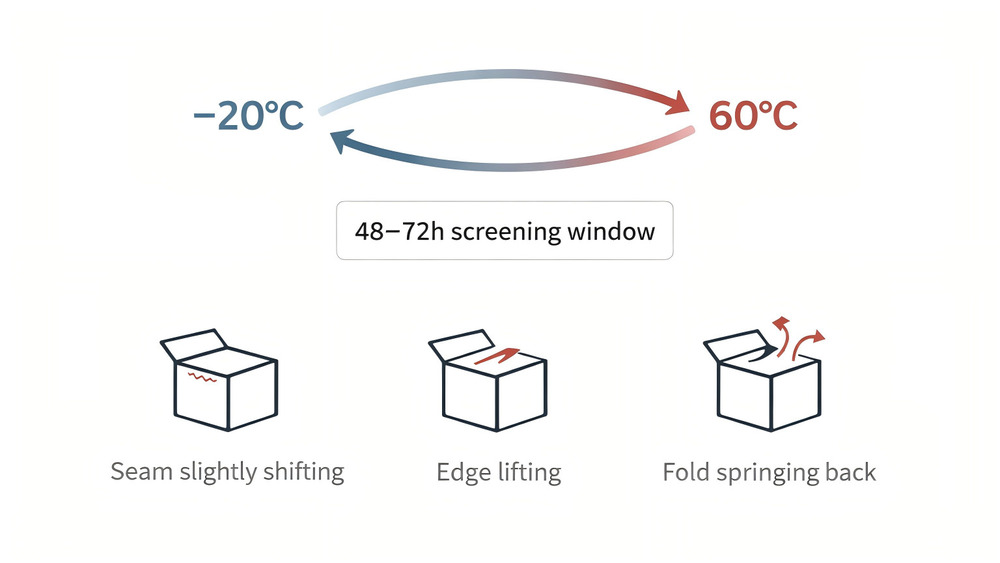

Temperature Cycling (–20°C to 60°C): What It Exposes Quickly

Adhesive Creep and Cold Brittleness

Temperature cycling moves packaging through cold and heat in short, repeated steps.

In practice, 48–72 hours is a common baseline window for observation. It does not explain why failures occur. It shows what breaks first.

Some adhesive bonds appear stable at room temperature but begin to shift during the warm phase, or crack and open during the cold phase.

During cycling, tabs may loosen, seams may drift, and glued areas may lose alignment—often within the first one to two days.

Lamination and Wrap Lift

Wraps and films that remain flat under steady temperature can start to lift at edges and corners when exposed to repeated temperature swings.

Curling, bubbling, or edge separation typically appears early, especially where edge tension or bonding pressure is already marginal.

Fold Fatigue and Structural Rebound

Creases that seem stable at rest can weaken under repeated cold-to-heat movement.

After multiple cycles, folds lose memory, panels spring back, and the structure no longer holds its intended shape.

A key advantage of temperature cycling is speed.

A 48–72 hour cycling window is often enough to expose marginal glue choices, lamination methods, or fold designs—before committing to longer or more expensive testing.

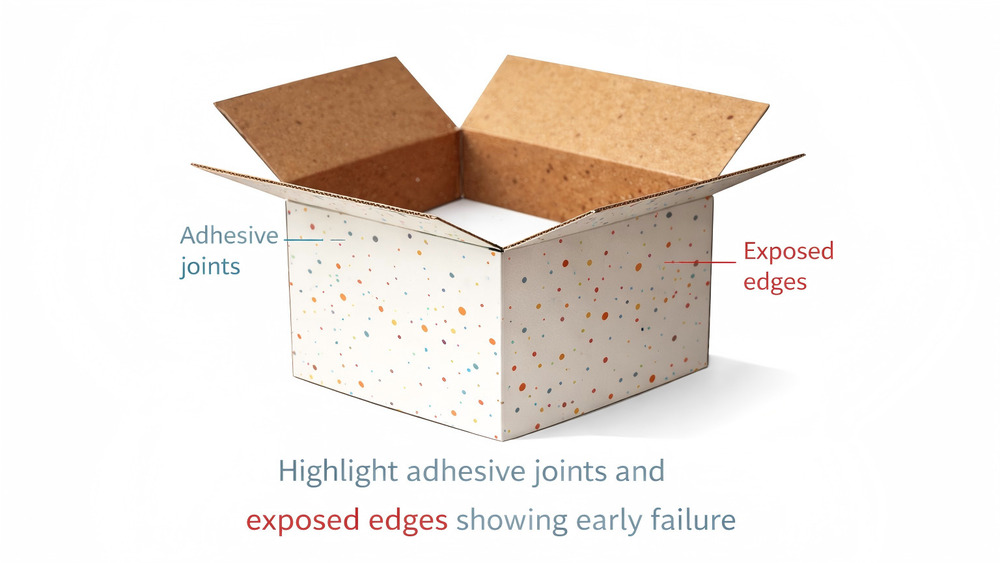

Why Unboxed Testing is the “Stress Test” for Adhesive Integrity

No Outer Carton Means No Protection Margin

In unboxed testing, there is no outer carton.

That means adhesive joints and edges are fully exposed.

What we see is not whether failure happens,

but where it happens first.

Adhesive joints loosen earlier.

Edges lift or separate sooner.

Issues that might hold for a while in boxed conditions show up much faster when tested unboxed.

Unboxed testing feels more stringent

not because the conditions are harsher,

but because there is no protection margin hiding weak points.

What Unboxed Testing Cannot Represent

Unboxed testing exposes problems quickly, but it does not represent full boxed shipment conditions.

It does not reflect moisture buildup inside an outer carton.

It does not account for stacking compression.

And it does not capture failures that only develop over time.

Its value lies elsewhere.

Unboxed temperature cycling is not a transport simulation.

It is often the fastest and most effective filter that prevents unacceptable packaging failures from ever reaching the end user.

What Extreme High-Humidity Testing Is Really Simulating

Extreme high-humidity testing is not about making conditions more severe.

It is designed to simulate a different category of transportation risk.

In real logistics, this risk is commonly associated with cargo sweat, or container condensation.

During long shipments, humidity can remain elevated for extended periods, with temperature changes causing repeated condensation that may come into direct contact with the packaging.

As a result, this testing focuses less on short-term fluctuations,

and more on sustained high-humidity exposure under variable temperature conditions.

The purpose of extreme high-humidity testing is a shift in risk perspective.

It is not an intensified version of 60% RH testing, nor an extension of temperature cycling.

It is used to assess whether packaging can maintain basic structure and usability

when exposed to prolonged, high-humidity transport environments.

When Extreme High-Humidity Testing Is Necessary (Yes)

Extreme high-humidity testing with extended exposure duration is only necessary under specific conditions.

If any of the following applies, this type of testing should be considered.

. High-value or moisture-sensitive products

When the product is high in value or inherently sensitive to moisture,

a packaging failure under sustained humidity would be unacceptable.

. Known high-humidity routes or documented incident history

If the shipment route involves persistently humid environments,

or if there is prior history of condensation, moisture damage, or related complaints,

the test is addressing a known risk, not a theoretical one.

Based on our shipping data to Southeast Asia and the Middle East, container temperatures can hit 60°C with 90% humidity within 48 hours.

. New structure, new materials, or first-time collaboration

When the packaging design, material combination, or supplier relationship lacks historical data,

extended high-humidity testing helps cover unknown exposure risk.

. Customer-mandated long-duration humidity requirements

If sustained high-humidity conditions are explicitly specified in customer standards, contracts, or acceptance criteria,

the test is a requirement, not an optimization choice.

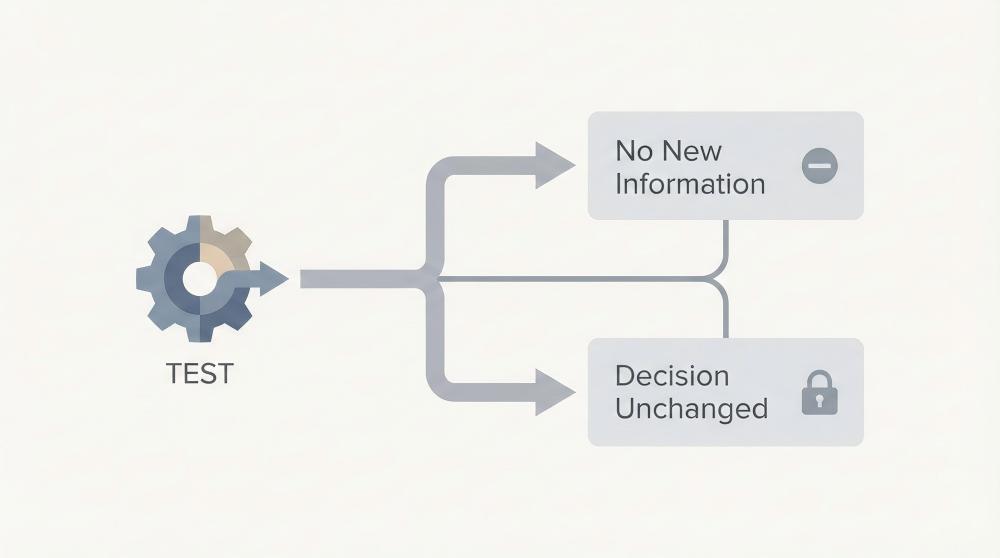

When It’s Usually a Budget Waste (No)

In many projects, extreme high-humidity testing with extended exposure does not provide new information.

When the conditions below apply, the test usually consumes budget without changing the decision.

. Mature structure with a long, stable shipping record

The packaging has been produced and shipped repeatedly

under similar conditions, with no humidity-related issues.

Running the test again typically confirms one thing:

nothing changed.

. Outer carton with standard moisture protection already in place

The product is shipped with an outer carton

and basic moisture controls such as liners, desiccants, or standard barriers.

If a failure were to occur,

it would usually show up first in adhesives or process execution, not after prolonged humidity exposure.

. Risk is already known to be in adhesives or process stability

When past issues clearly point to glue selection, application consistency, or folding control,

extreme high-humidity testing adds little value.

After the test, you still have to go back and fix the process.

. Used only for routine reassurance

If the goal is simply to “check one more box,”

without a clearly defined transport exposure risk,

the test is more likely to delay decisions than reduce failure.

Risk note

If shipment routes, materials, or customer requirements change,

a test that was previously wasteful may need to be reconsidered.

Decision Matrix: Choosing the Right Test for the Right Scenario

| Scenario | Recommended Test | Why |

|---|---|---|

| Normal sea freight | 60% RH + temperature cycling | Screen adhesive performance and overall process stability |

| Tropical / monsoon routes | 85–90% RH testing | Address prolonged high-humidity exposure that can lead to material softening |

| Early unboxed structural screening | Unboxed + temperature cycling (–20°C / 60°C) | Confirm that structure and adhesive joints show no early failure before boxed or high-humidity testing |

The purpose of this matrix is not to select the harshest test,

but to avoid spending time and budget on tests that do not change the decision.

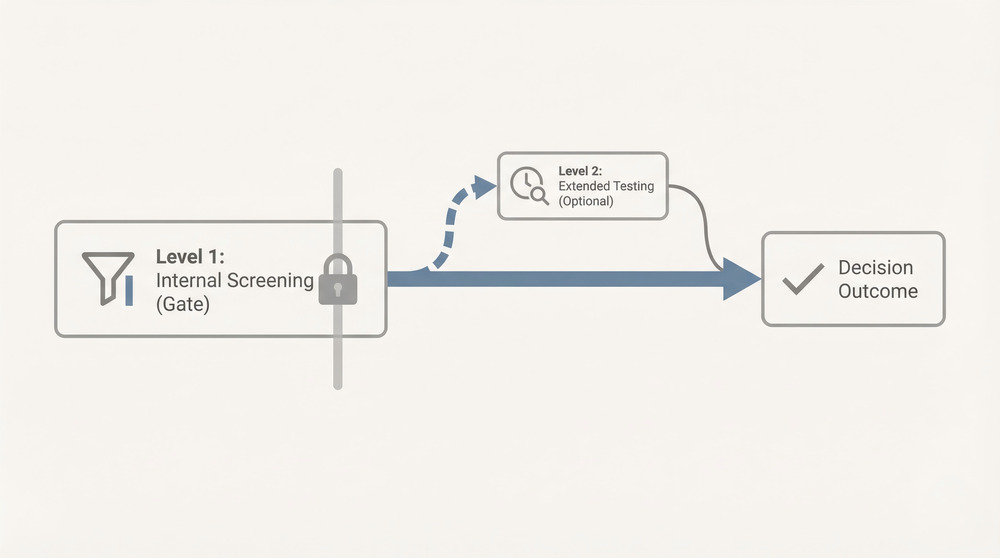

A Simple Two-Level Testing Approach That Works in Practice

In real projects, we rarely expand all tests at the beginning.

The reason is simple: many packaging concepts never make it past the first gate.

Our approach is intentionally restrained.

We screen out what clearly does not hold first,

before deciding whether it is worth going further.

| Test Level | Condition | Primary Goal | Who Needs This? |

| Level 1 (Standard) | 60% RH + Temp Cycling | Ensure glue & process stability | 100% of all projects |

| Level 2 (Advanced) | 85-90% RH | Simulate extreme maritime risk | High-value / Humidity-sensitive items |

Level 1: Internal Screening Comes First

Level 1 is not meant to prove that a package is “acceptable.”

It is meant to answer one practical question early:

do the structure, adhesive joints, and process execution show any early risk?

Goal: Screen out solutions that shouldn’t leave the factory.

This aligns with our standard Quality Control protocols to ensure process stability.

This level typically includes:

- 60% RH as a baseline stability check

- Temperature cycling between –20°C and 60°C

- Direct observation of structure and adhesive performance in unboxed condition

At this stage, most unstable designs reveal themselves.

If joint loosening, rebound, edge lift, or inconsistency already appears here,

moving into long-duration or high-humidity testing

usually just takes longer to reach the same conclusion: redesign is needed.

Level 2: Only When There Is a Real Reason

Only when Level 1 is stable,

and when there is a real long-duration humidity exposure risk

or a clear customer requirement, do we proceed to this stage.

At this point, testing is no longer about catching obvious issues.

It is about confirming whether

transport conditions introduce risks that Level 1 could not reveal.

The value of this two-level approach is straightforward:

knowing when to stop is just as important as knowing when to test further.

Frequently Asked Questions (Decision-Oriented)

How long should high-humidity testing last for my project?

Klong’s Judgment: Most structural or adhesive failures surface within 48 to 72 hours. If a design is stable after three days, extending the test rarely changes the final decision—it only increases your lead time. If it’s going to fail, it almost always happens on day one.

Is 60% RH testing enough for high-end printed packaging?

Klong’s Judgment: Yes, as a baseline filter. 60% RH is the gold standard for verifying manufacturing process stability. We only recommend moving to 85%+ RH after the 60% baseline is proven stable; otherwise, you are simply testing a flawed process under harsher conditions.

Do all export packaging projects require extreme high-humidity testing?

Klong’s Judgment: No. Applying extreme testing to every project is often a budget waste. We only advise it when the Cost of Failure (high-value goods or tropical routes) outweighs the testing expense. For proven designs on stable routes, your historical shipping data is a more reliable safety net.

Final Takeaway: Testing Should Reduce Risk, Not Create Waste

If a test does not change the decision, it changes nothing.